Governors in the Field of Mechanical Engineering: An Overview

In mechanical engineering, precision and control are essential, especially when managing the operation of engines and machines. One of the most vital components ensuring stable and reliable performance in such systems is the governor. From steam engines in the Industrial Revolution to modern internal combustion engines and industrial turbines, governors play a crucial role in maintaining speed and performance. This article delves into the importance, types, working principles, and applications of governors in mechanical engineering.

What Is a Governor?

A governor is a device used to regulate the speed of an engine or machine. Adjusting the fuel or energy input maintains a desired operational speed, compensating for variations in load and preventing engine overspeed or underspeed. This self-regulating mechanism ensures safety, efficiency, and consistent output.

The Evolution of Governors

The concept of governors dates back to the early steam engines of the 18th and 19th centuries. James Watt, one of the pioneers of modern engineering, developed the centrifugal governor to control the speed of steam engines. This innovation was a breakthrough that significantly improved the reliability and efficiency of machinery during the Industrial Revolution. Over time, the design and application of governors evolved to meet the demands of more advanced and diverse machinery.

Types of Governors

Governors can be broadly classified into two main categories: centrifugal governors and inertia governors. Each type operates on different principles and serves specific applications.

Centrifugal Governors:

Watt Governor: The earliest and simplest form, relying on centrifugal force and gravity. It is most effective at lower speeds.

Porter Governor: A modification of the Watt governor with an additional central weight, enhancing speed regulation at moderate engine speeds.

Proell Governor: A more sensitive type, capable of responding to smaller speed variations.

Hartnell Governor: A spring-loaded governor that uses a helical spring to provide more precise speed control, commonly used in high-speed engines.

Inertia Governors:

Unlike centrifugal governors, inertia governors use the angular acceleration of the engine shaft to actuate the controlling mechanism. This type is typically employed where quick responses to speed changes are necessary.

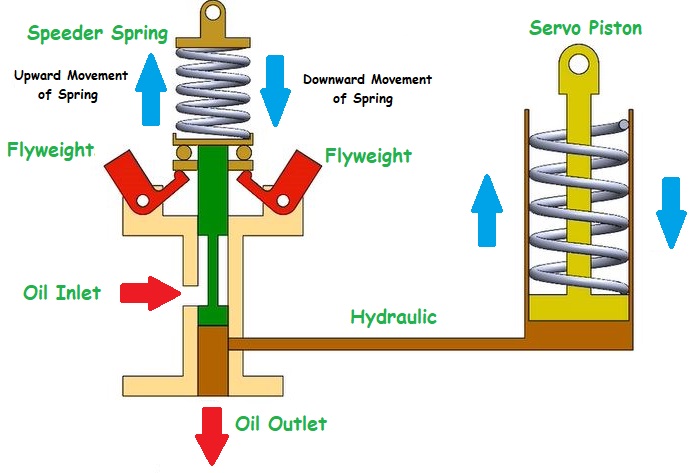

Working Principle of Centrifugal Governors

The fundamental working of a centrifugal governor involves rotating flyweights attached to a spindle driven by the engine. As the speed of the engine increases, the centrifugal force acting on the flyweights also increases, causing them to move outward. This movement adjusts a linkage connected to the fuel valve, reducing the energy input and thereby lowering the speed. Conversely, if the speed drops, the flyweights move inward, opening the valve wider to increase the fuel input and restore the speed.

Applications of Governors in Modern Mechanical Systems

Governors are integral to various modern mechanical and automotive systems. Some key applications include:

Automotive Industry: Speed governors in vehicles prevent them from exceeding set speed limits, enhancing safety and fuel economy.

Power Generation: Governors in turbines regulate the rotational speed to ensure consistent power output and prevent overspeed conditions.

Industrial Machinery: Equipment such as compressors and pumps use governors to maintain operational efficiency under fluctuating loads.

Marine and Aerospace: High-performance engines in ships and aircraft require precise speed control to operate safely and efficiently.

Advancements in Governor Technology

With the advent of electronic and digital control systems, traditional mechanical governors have evolved into sophisticated electronic governors. These modern systems use sensors, actuators, and microprocessors to achieve finer control, faster response times, and greater reliability. Integrating feedback mechanisms and real-time data processing has opened up new possibilities for highly adaptive and efficient speed regulation.

Conclusion

Governors remain a cornerstone in the field of mechanical engineering, bridging the gap between traditional mechanical systems and modern electronic controls. Understanding their operation, types, and applications is crucial for engineers designing systems requiring precision and stability. As technology advances, governors will continue to adapt, ensuring they meet the needs of increasingly complex mechanical systems.

Comments

Post a Comment