Additive Manufacturing: A Clear Cut View- BLOG 1

Additive Manufacturing(AM) is the process of fabricating the 3D model into required object by depositing the material layer by layer, also known as 3D printing. It is the is a revolutionary technology that is rapidly changing the way we design and manufacture products. Unlike traditional subtractive methods that remove material from a solid block, AM builds objects layer by layer using a variety of materials, including plastics, metals, ceramics, and even living cells.

Points to be noted for 3D Printing:

- Design the model

- convert the model into STL file

- Slicing

- Tessellation

- Type of Additive Manufacturing(AM)

STL File:

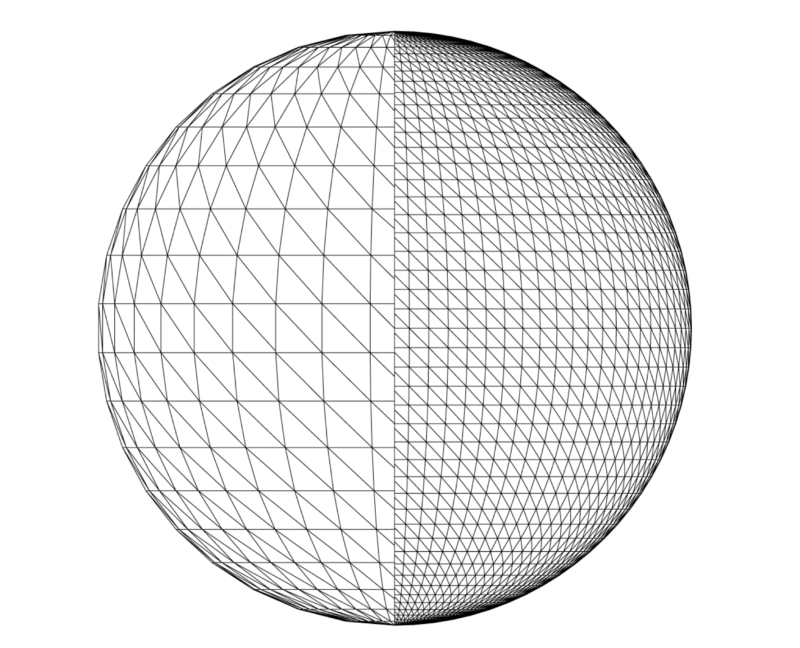

The STL file format is the key component of this procedure. The 3D object is represented in this file as a mesh-like arrangement of triangular facets. The surface geometry of the item is defined by the information that each facet contains about its points and normal vector. Because so many different 3D design and slicing programs use STL files, they are an essential part of the AM procedure.

Slicing:

Before printing, the STL file undergoes a process called slicing. This involves dividing the object into many thin layers, typically ranging from 0.05 to 0.3 mm in thickness. Each layer essentially becomes a 2D image that guides the material deposition process during printing.

|

| Slicing[2] |

Tessellation:

|

Tessellation[3] |

Types of Additive Manufacturing Techniques:

There are many different types of AM technologies, each with its own advantages and limitations. Some of the most common types include:

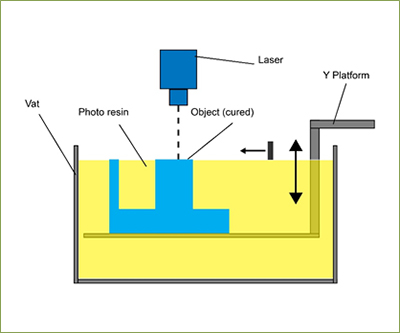

Vat Photopolymerization (SLA): 👈This technology uses an ultraviolet light source to cure a liquid resin layer by layer. It offers smooth surface finishes and high accuracy, making it ideal for creating prototypes and models.

|

| Vat Photopolymerization[4] |

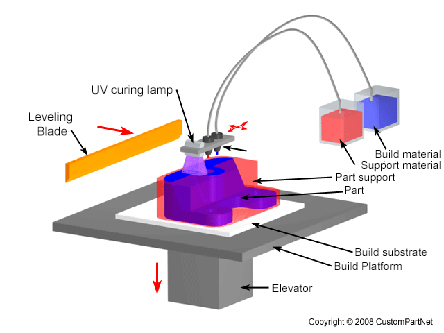

Material Jetting:👈 This technology uses a jet of material to build the object layer by layer. It offers high speed and accuracy, making it suitable for industrial applications.

|

| Material Jetting[5] |

|

| Binder Jetting[6] |

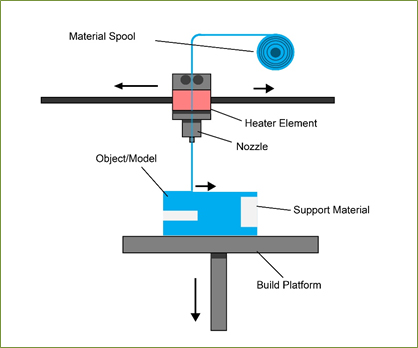

|

| Material Extrusion[7] |

References:

- https://www-objects.markforged.com/craft/common/_small/STL-Sphere.png

- https://assets.epicurious.com/photos/593045d0b676c07b387fb46e/16:9/w_2560%2Cc_limit/HOW-TO-CUT-WATERMELLON-25052017-001.jpg

- https://media.istockphoto.com/id/1220443934/vector/vector-seamless-geometric-pattern-simple-abstract-lines-lattice-repeating-elements-stylish.jpg?s=612x612&w=0&k=20&c=G67a3yJG5nQzg5kgU3m545InxCE69tuMOBlGi7jceYY=

- https://www.lboro.ac.uk/media/wwwlboroacuk/external/content/research/amrg/powderbedfusion%20-%20process.jpg

- https://www.lboro.ac.uk/media/wwwlboroacuk/external/content/research/amrg/material_jetting_process.jpg

- https://www.lboro.ac.uk/media/wwwlboroacuk/external/content/research/amrg/binderjetting-process.jpg

- https://www.lboro.ac.uk/media/wwwlboroacuk/external/content/research/amrg/material%20extrusion%20-%20process.jpg

- https://www.lboro.ac.uk/media/wwwlboroacuk/external/content/research/amrg/sheetlamination%20-%20process.jpg

- https://www.lboro.ac.uk/media/wwwlboroacuk/external/content/research/amrg/vat-process.jpg

- https://www.lboro.ac.uk/media/wwwlboroacuk/external/content/research/amrg/Direct%20Energy%20Deposition%20-%20process.jpg

Comments

Post a Comment